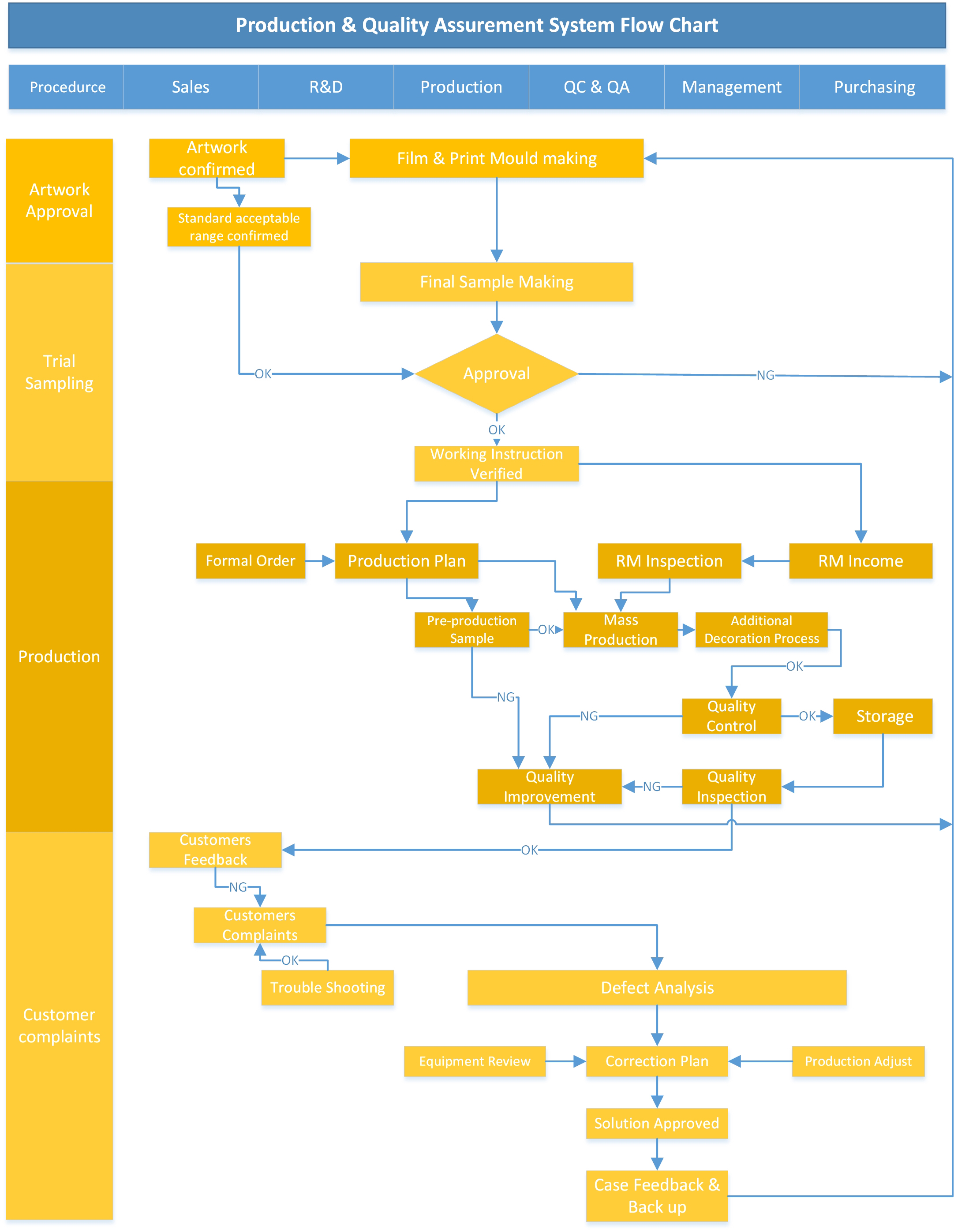

Quality Control

As a reliable partner and certified supplier of the world’s leading beauty business sustain success and to keep quality standards great, we aim to provide clients with comprehensive satisfaction by Continuous quality improvement by processes with validation structures. Cosjar concentrates on continuous improvement – of people, products and processes, scientific knowledge of packaging safety. Our company, Taiwan K.K, drives excellence and creativity across all industries concentrates enthusiasm on every aspect to establish the enterprise culture of service perfection, quality superiority, and never-ending research, development and improvement. This has laid the foundations for the responsible and effective implementation of quality assurance systems in business with global market access.

In our production process, we have a number of measures to ensure the quality of our products, briefly described as following:

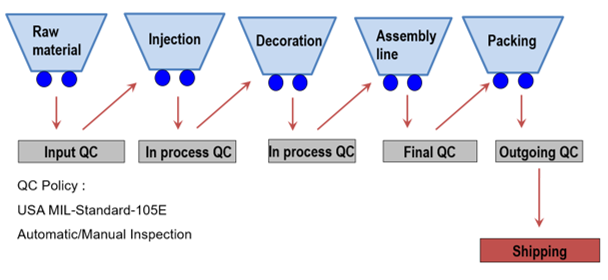

MATERIAL: (Input QC)

From the beginning of production, the material of acrylic will go through dust blow off phase to clean impurities and black spots in the plastic raw material.

INJECTING / BLOWING: (In process QC)

Our quality inspector will examine the containers as they come out of the injecting or blowing equipment. We will remove any packaging that has bubbles, black dots, or scratches from the production line to recycle room.

DECORATING / PRITING: (In process QC)

At the decoration stage, we will examine the product outcome after each procedure such as spray painting, hot-stamping, silk screen printing etc. for imperfections, wrong position, or color mismatching. If there’s any visible problem on the parts, it will be discarded.

ASSEMBLING / PACKAGING / SHIPPING: (Final QC)

At this stage, we will check the entire batch of packaging after it is assembled and random check (Outgoing QC) when they are packed into the cartons for shipping. This final step also complies with MIL standard 105E, and will make sure the quality is consistent.

Shipment release is under quality assurance.

Even we cannot guarantee that we are the best in the field, but we can assure you that we will keep improving as much as we can.

The philosophy of ISO management has been followed to carry out strict and constant quality control for all incoming raw materials, empty components, semi-finished products and finished products.

Insisting on high quality to satisfy our customers, we had rebuilt our second factory in year 2001 and enlarge the space.

The philosophy of ISO management has been followed to carry out strict and constant quality control for all incoming raw materials, empty components, semi-finished products and finished products.

Shipment release is under quality assurance.

We cannot guarantee that we are the best in the field, but we can assure you that we will keep improving as much as we can.

Meticulously crafted to offer durability, functionality, and style for all your packaging needs.

Quality Control | Innovative and Sustainable Beauty Packaging by COSJAR

COSJAR, established in 1976 and based in New Taipei City, Taiwan, excels in high-quality acrylic beauty packaging. We specialize in plastic bottles, cosmetic containers, and skincare solutions. Renowned for our durable and visually appealing designs, we lead the beauty industry in innovation and sustainability. From lotion bottles to cream jars, our eco-friendly packaging meets the diverse needs of global beauty brands. With a focus on precision, sustainability, and customer satisfaction, COSJAR enhances the aesthetics and functionality of your beauty products.

Our state-of-the-art manufacturing processes ensure precise, high-quality acrylic packaging that aligns with modern cosmetic and skincare trends. We provide a one-stop shopping service from design to quality control, catering to diverse packaging needs with various materials and customized decorations. COSJAR emphasizes sustainability and continuous improvement, offering eco-friendly options and maintaining ISO 9001 certification to guarantee top-tier product quality and reliability for global beauty brands.

COSJAR has been offering customers environmentally friendly packaging solutions to worldwide customers, both with advanced technology and 47 years of experience, COSJAR ensures each customer's demands are met.