COSJAR’s Packaging Production and Quality Inspection

2015/07/20 Author: COSJAR Sales TeamAs we work with clients from around the world, we contribute with utmost quality standard and inspection level to make sure the acrylic packaging for your product is the most outstanding on the market!

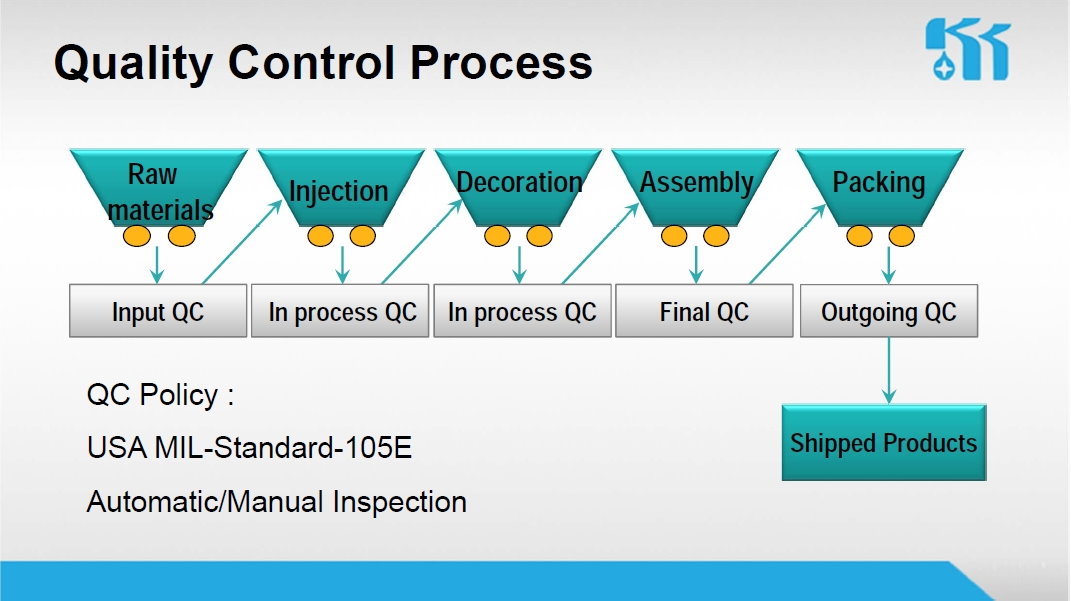

In our production process, we have a number of measures to ensure the quality of our products, briefly described as following:

MATERIAL: (Input QC)

From the beginning of production, the material of acrylic will go through dust blow off phase to clean impurities and black spots in the plastic raw material.

INJECTING / BLOWING: (In process QC)

Our quality inspector will examine the containers as they come out of the injecting or blowing equipment. We will remove any packaging that has bubbles, black dots, or scratches from the production line to recycle room.

DECORATING / PRITING: (In process QC)

At the decoration stage, we will examine the product outcome after each procedure such as spray painting, hot-stamping, silk screen printing etc. for imperfections, wrong position, or color mismatching. If there’s any visible problem on the parts, it will be discarded.

ASSEMBLING / PACKAGING / SHIPPING: (Final QC)

At this stage, we will check the entire batch of packaging after it is assembled and random check (Outgoing QC) when they are packed into the cartons for shipping. This final step also complies with MIL standard 105E, and will make sure the quality is consistent.

With all the steps mentioned above, you can be sure that COSJAR has the best skincare packaging around. Talk to our sales team, or send us an inquiry to find out more about our products and services!